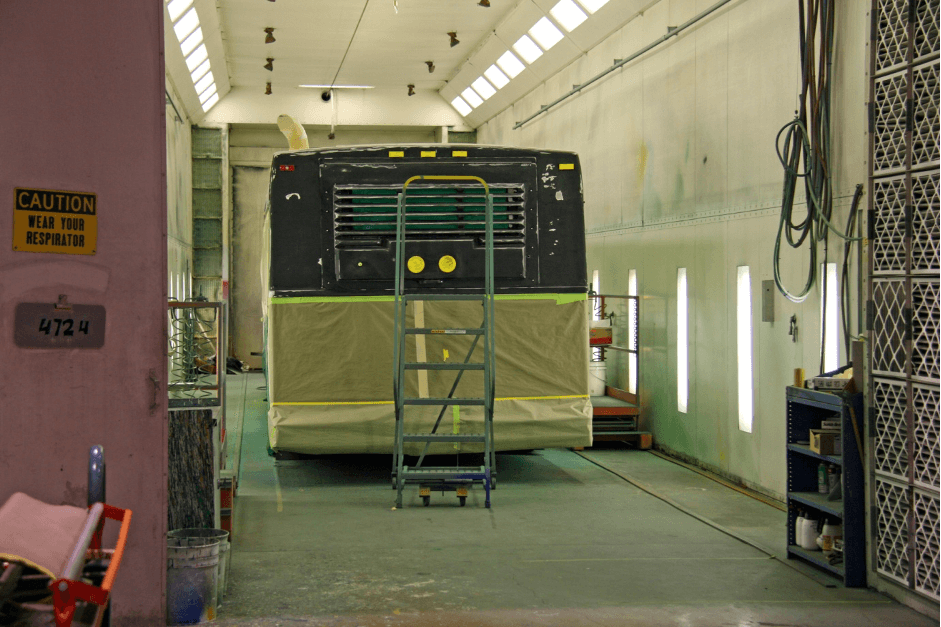

The controlled environment within a spray booth makes it a safer and more efficient way to paint on your outputs on the factory flow, resulting in a more attractive outcome. Using a sealed environment for spray painting prevents dust and other particles from contaminating the air affecting the final paint finish. There are generally two airflow systems within a spray booth, a cross draft system for moving air horizontally across the area and a downdraft system for forcing air downward.

Manufacturers often use spray booths to coat parts and products with paint or protective coatings. In addition to ensuring the safety of workers, booths are used to make painting and coating easier and faster. While spray booths are a significant investment, they are often costly investments, so you need to be sure to maintain and use your spray booth correctly. This way, you can get the most out of your booth while preventing the need to replace it.

The following tips can help to ensure your spray booth’s durability and healthiness.

Cleaning

To ensure longevity, it is necessary to perform routine cleanings. Even if your booth is only used a few times a week, it still needs to be cleaned regularly depending upon the frequency and nature to remove dirt, waste, and overspray contamination. Although it takes time to routinely clean a booth, a clean booth will always produce better results.

Better Equipment Operation

A spray booth’s life is often prolonged by the knowledge, attitude, and experience of the workers who work in it. Therefore, all operators should create comprehensive training programs along with mentoring and oversight for new workers. Workers should also know all necessary steps to clean the equipment properly to avoid any damage during the process.

Maintaining Filters

Each spray booth has a filtration system that collects hazardous compounds and recycles airflow to maintain a safe working environment. To keep the filtration system running correctly, operators need to be aware of its limitations and properties. Overused filters can put employees in danger and contribute to surface contamination during coatings or sprays. To protect your spray booth and retain durability, it is necessary to maintain and clean the filtration systems frequently.

Upgrades

Having upgrade options is one of the most significant benefits of a bespoke professional spray booth. The ability to adapt to growing production environments can be particularly relevant when demand is gradually increasing. With new filtration systems, you can encourage airflow and use your booth for more extended periods. The layout and design of the booth limit modifications, but a modest investment typically offers a degree of possibility for improving most units.

The most technologically advanced spray booths on the market are designed and built by DRYSYS, the leading manufacturer of spray booths across Australia. The spray booths we create for our clients are made to meet their specifications and integrate seamlessly into their production lines and control systems. We are a company with more than 15 years of industry experience and can create the perfect bespoke spray booth for your business.