Metrology, the science of measurement, plays a crucial role in various fields, from manufacturing and engineering to science and healthcare. It ensures that measurements are accurate, reliable, and consistent, which is essential for quality control, research, and daily life applications. So, what is metrology? This guide delves into the fundamentals, types, and importance of metrology, providing a comprehensive overview of this essential science.

What is Metrology?

Metrology deals with the science and act of measurement. Its scope includes theoretical as well as practical components with particular emphasis on introduction, maintenance and utilization of measurement systems. In so doing, it guarantees harmony of measurement, or rather goes a long way in ensuring that measurements could always be referred back to standards set at international level, thus facilitating reliable comparisons.

The Three Branches of Metrology

Metrology can be divided into three main branches: scientific metrology, industrial metrology, and legal metrology. Each branch serves a specific purpose and operates within distinct contexts.

Scientific Metrology

Scientific metrology focuses on developing and keeping measurement standards, in which a fundamental study is done to set and purify measurements as well as their correctness and exactness. For the advancement and diffusion of these standards, national metrological institutions including the National Institute of Standards and Technology (NIST) are at the center of this scientific field.

Industrial Metrology

Industrial metrology focuses on the application of measurement science in manufacturing and production processes. It ensures that instruments and measurements used in industries are accurate and reliable. This branch of metrology is crucial for quality control, product development, and maintaining consistency in production lines.

Legal Metrology

Legal metrology pertains to measurements that directly affect public safety, health, and fair trade. It involves the regulation and standardization of measuring instruments used in commerce, such as scales, gas pumps, and taxi meters. Legal metrology ensures that consumers receive accurate quantities and that measurements meet regulatory requirements.

Importance of Metrology

Metrology is vital for various reasons, impacting multiple aspects of society and industry. Its importance can be seen in the following areas:

Quality Control

In manufacturing, precise measurements are essential for producing high-quality products. Metrology ensures that components and products meet specified tolerances and standards. This precision reduces errors, minimizes waste, and enhances product reliability.

Scientific Research

Accurate measurements are the backbone of scientific research. Metrology provides the tools and standards necessary for scientists to conduct experiments, gather data, and validate hypotheses. Consistent measurements enable reproducibility and comparability in research findings.

Healthcare

In healthcare, accurate measurements are critical for diagnosis, treatment, and monitoring of patients. Metrology ensures the reliability of medical instruments, such as blood pressure monitors, thermometers, and imaging devices. This accuracy is vital for patient safety and effective medical care.

Trade and Commerce

Metrology plays a crucial role in trade and commerce by ensuring fair transactions. Accurate measurements are necessary for determining quantities of goods, calculating prices, and verifying compliance with trade regulations. Legal metrology protects consumers and maintains market integrity.

Safety and Compliance

In areas such as aviation, car manufacture among others, accuracy is necessary for safe conduct in accordance with standard. This is regardless of whether you are building machines that fly people to various destinations world over or designing automobiles that can transport passengers in and out of city centers.

Fundamental Concepts in Metrology

There are a few basic concepts that underlie metrology, which we must understand if we are to fully appreciate what measurement science is about.

Units of Measurement

Units of measurement are standardized quantities used to express physical properties. The International System of Units (SI) is the globally accepted system for measurement, comprising seven base units: meter (length), kilogram (mass), second (time), ampere (electric current), kelvin (temperature), mole (amount of substance), and candela (luminous intensity). These units form the foundation for all other measurements.

Measurement Standards

Measurement standards are reference materials or devices with known properties used to calibrate instruments and validate measurements. These standards ensure consistency and traceability in measurements. Primary standards are maintained by national metrology institutes, while secondary standards are used in industrial and commercial settings.

Calibration

Calibration is the process of comparing a measuring instrument to a known standard to determine its accuracy and adjust it if necessary. Regular calibration is essential to maintain the reliability and precision of measurement instruments. It involves assessing the instrument’s performance and correcting any deviations from the standard.

Uncertainty

Measurement uncertainty is the quantification of doubt in a measurement result. It reflects the confidence level in the accuracy of the measurement. Uncertainty arises from various sources, including instrument limitations, environmental factors, and operator variability. Understanding and minimizing uncertainty is crucial for reliable measurements.

Traceability

Traceability refers to the ability to relate individual measurement results to national or international standards through an unbroken chain of comparisons. It ensures that measurements are consistent and comparable across different locations and times. Traceability is essential for maintaining the integrity of measurement systems.

Metrology in Practice

Metrology is applied in various practical scenarios, each requiring specific techniques and instruments. Some common applications include:

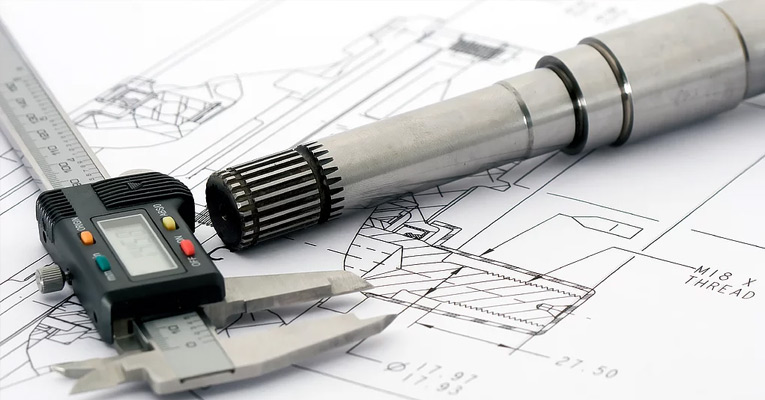

Dimensional Metrology

Dimensional metrology involves measuring physical dimensions, such as length, width, height, and angles. It uses tools like calipers, micrometers, and coordinate measuring machines (CMMs) to ensure precision in manufacturing processes.

Mass and Weight Measurement

Accurate measurement of mass and weight is crucial in industries like pharmaceuticals, food, and logistics. Balances and scales are calibrated against standardized weights to ensure accuracy.

Temperature Measurement

Temperature measurement is vital in many fields, including meteorology, healthcare, and industrial processes. Thermometers, thermocouples, and infrared sensors are calibrated to ensure accurate temperature readings.

Electrical Measurement

Electrical metrology involves measuring electrical properties such as voltage, current, and resistance. Instruments like voltmeters, ammeters, and ohmmeters are calibrated against electrical standards to maintain accuracy.

Conclusion

Metrology, the science of measurement, is fundamental to various aspects of society and industry. It ensures the accuracy, reliability, and consistency of measurements, which are essential for quality control, scientific research, healthcare, trade, and safety. By understanding the principles and applications of metrology, we can appreciate its critical role in our daily lives and technological advancements. Whether it’s through scientific research, industrial applications, or legal regulations, metrology continues to be a cornerstone of progress and precision.